Production Specifications

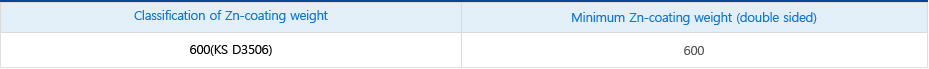

2. Materials

2.1 Quality of Materials

-

2.1.1 C.S.P are made of hot-rolled hot dip galvanized steel plates complying with KS D 3506.

-

2.1.2 Minimum Zn-coating weight of hot dip galvanized steel plate is as shown below.

-

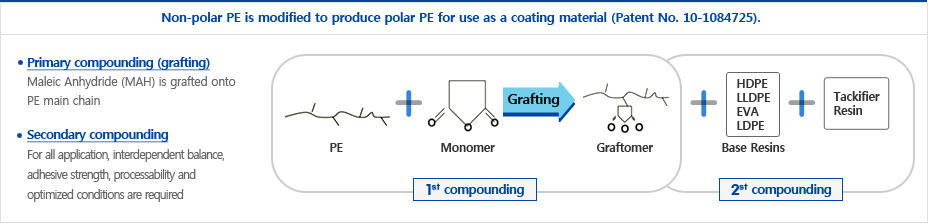

2.1.3 Coating materials used are as described below.

- 2.1.3.1 For the first coating, an adhesive resin (maleic acid-modified polyethylene 30 % and polyethylene resin 50 %) is used, applying KS F4737 for adhesive strength (14~20 kgf/25 mm) and KS B ISO 13565-1 for surface roughness (1~5㎛). (Patent No. 10-1084725)

-

- 2.1.3.2 he second coating is done to obtain an optimal melt flow index (MI) of 10~50 g/10 min and adhesive strength of 14~20 kgf/25 mm) using high-density polyethylene (non-polar PE).

-

2.1.4 Sealant that is injected into the lock-seam of the corrugated steel spiral pipe to block water leakage.

- 2.1.4.1 Unsaturated or reactive polyolefin to which monomers containing polar groups are grafted, and an organic silicon compound (maleic acid-modified polyethylene + organic silicon)

- 2.1.4.2 The composition of the sealant is as shown below.

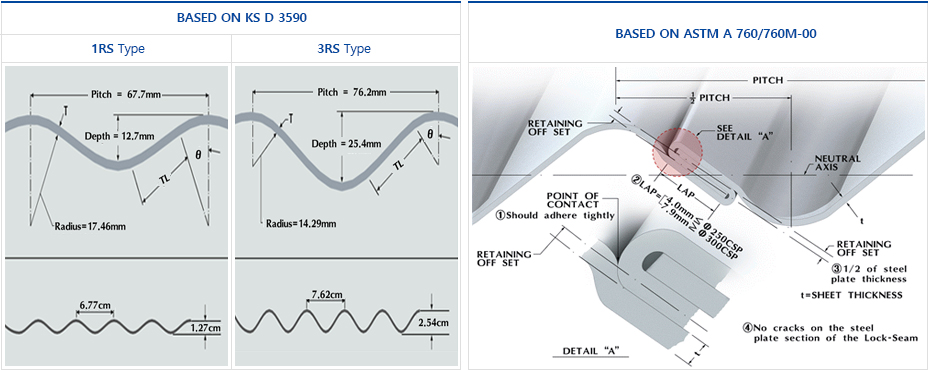

2.2 Shape and size (1RS & 3RS); Based on KS D 3590 and ASTM A 760/760M-00

-

2.2.1 Shape

-

2.2.2 Sectional Dimensions

-

2.2.3 Allowable deviation in size

-

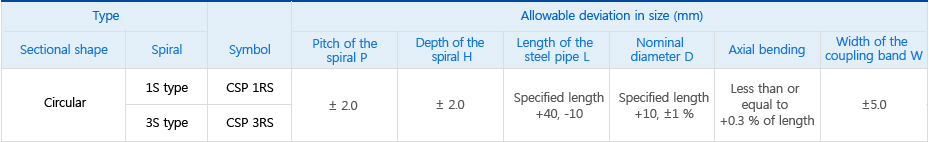

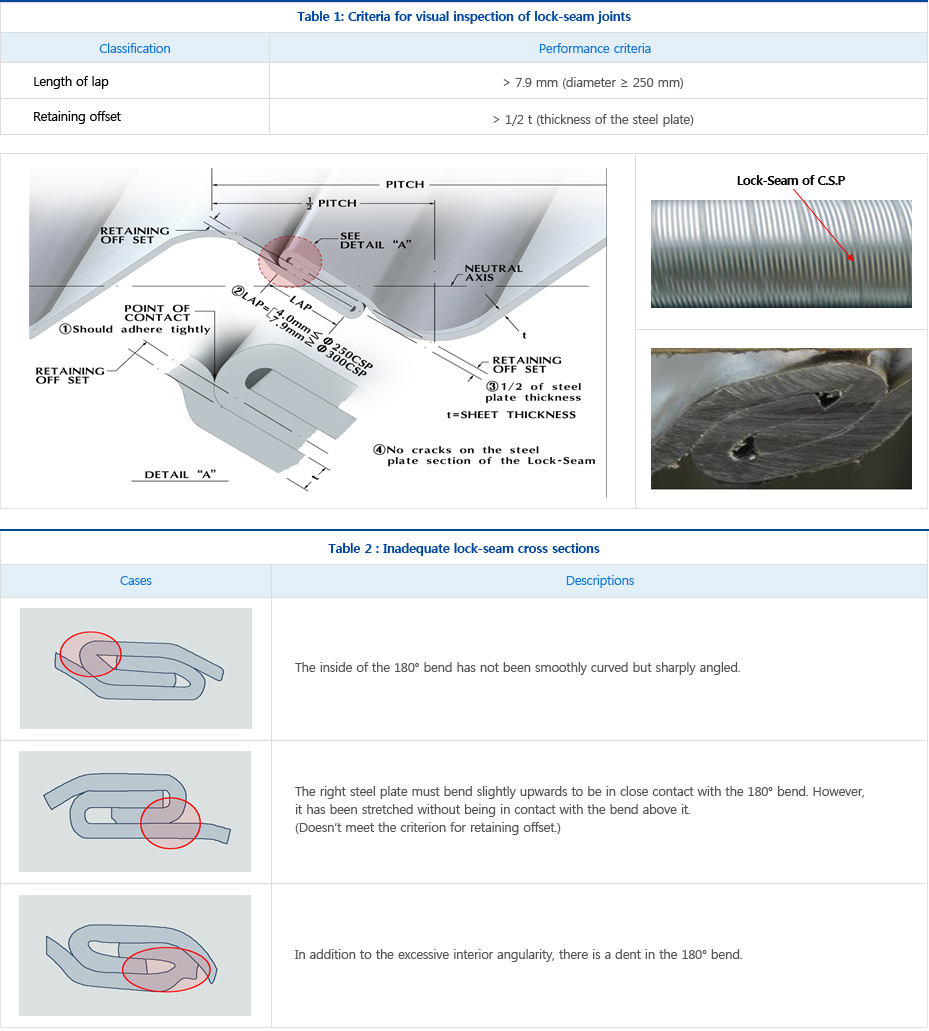

2.2.4 Criteria for (lock-seam) joints of C.S.P

- 2.2.4.1 The criteria to be met during visual inspection of lock-seam joints of C.S.P are as shown in 《Table 1》 below, for the respective thicknesses of the steel plates (1.6t, 2.0t, 2.7t, 3.2t), and they shall not be of shapes shown in 《Table 2》.

-

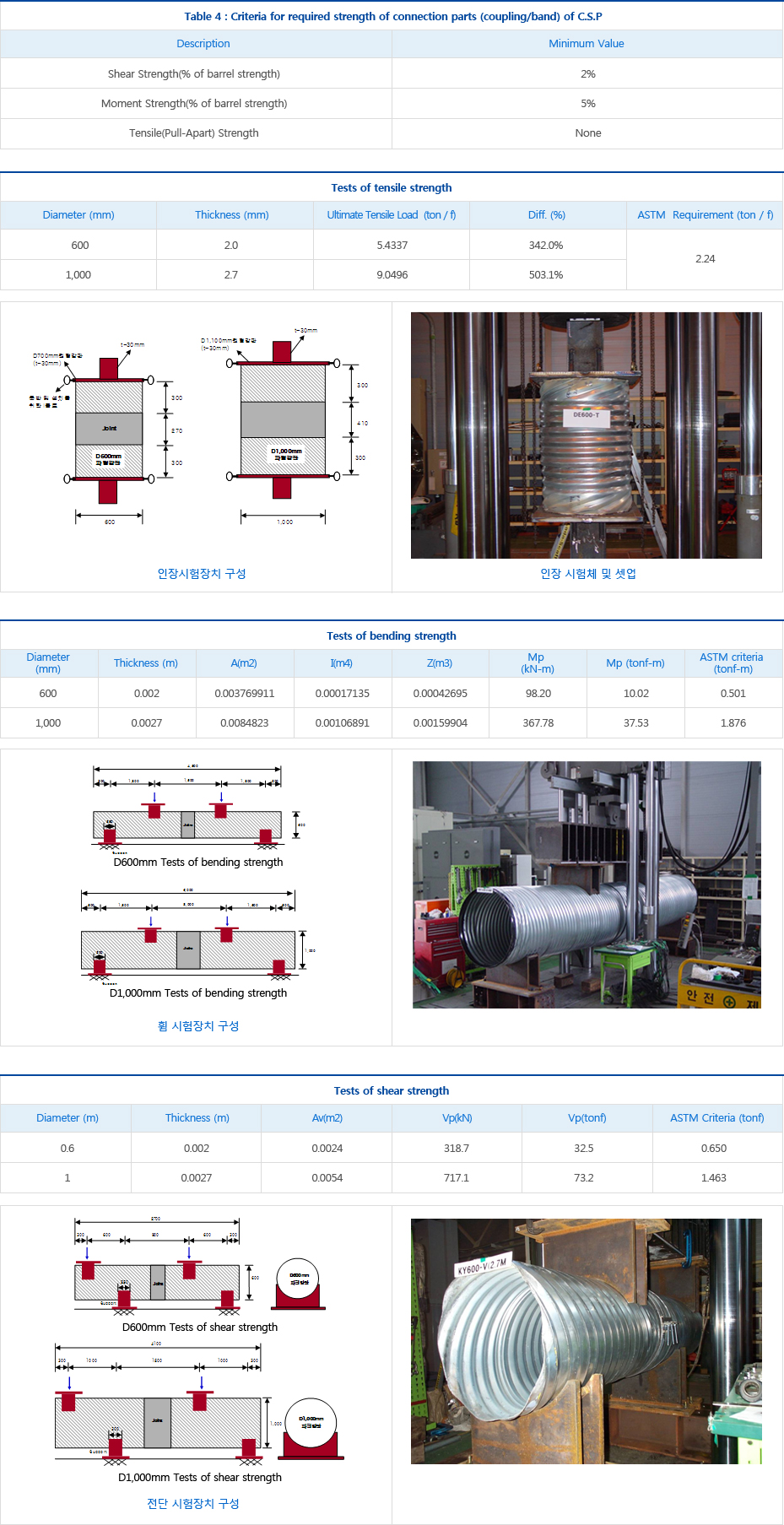

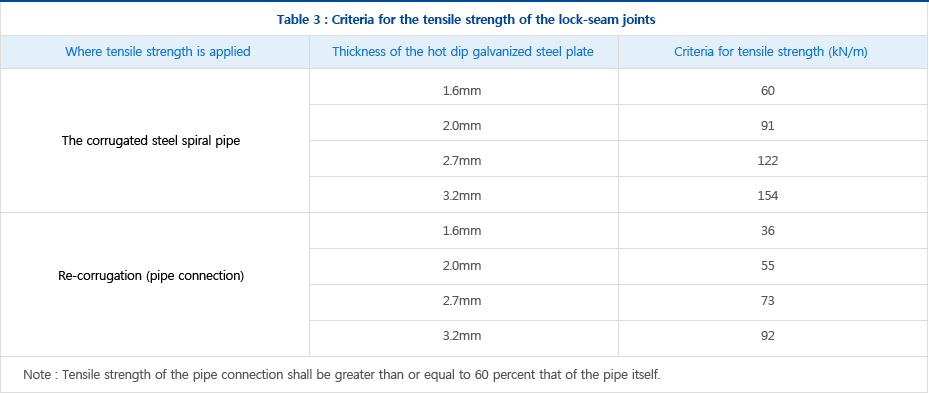

- 2.2.4.2 Criteria for tensile strength of lock-seam joints are as shown in Table 3 below, and the tensile strength of the object being tested shall be greater than or equal to the corresponding value in the table.

-

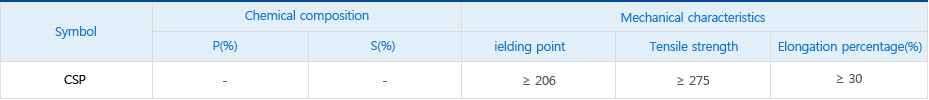

2.2.5 Coupling∙band for connecting pipes

- 2.2.5.1 The structural performance of the coupling parts of corrugated steel spiral pipes, such as tensile strength, bending strength, shear strength, etc., shall meet the criteria shown in Table 4 below, and this shall be verified using at least two applicable standards.