Production Specifications

1. General

1.1 Range of application

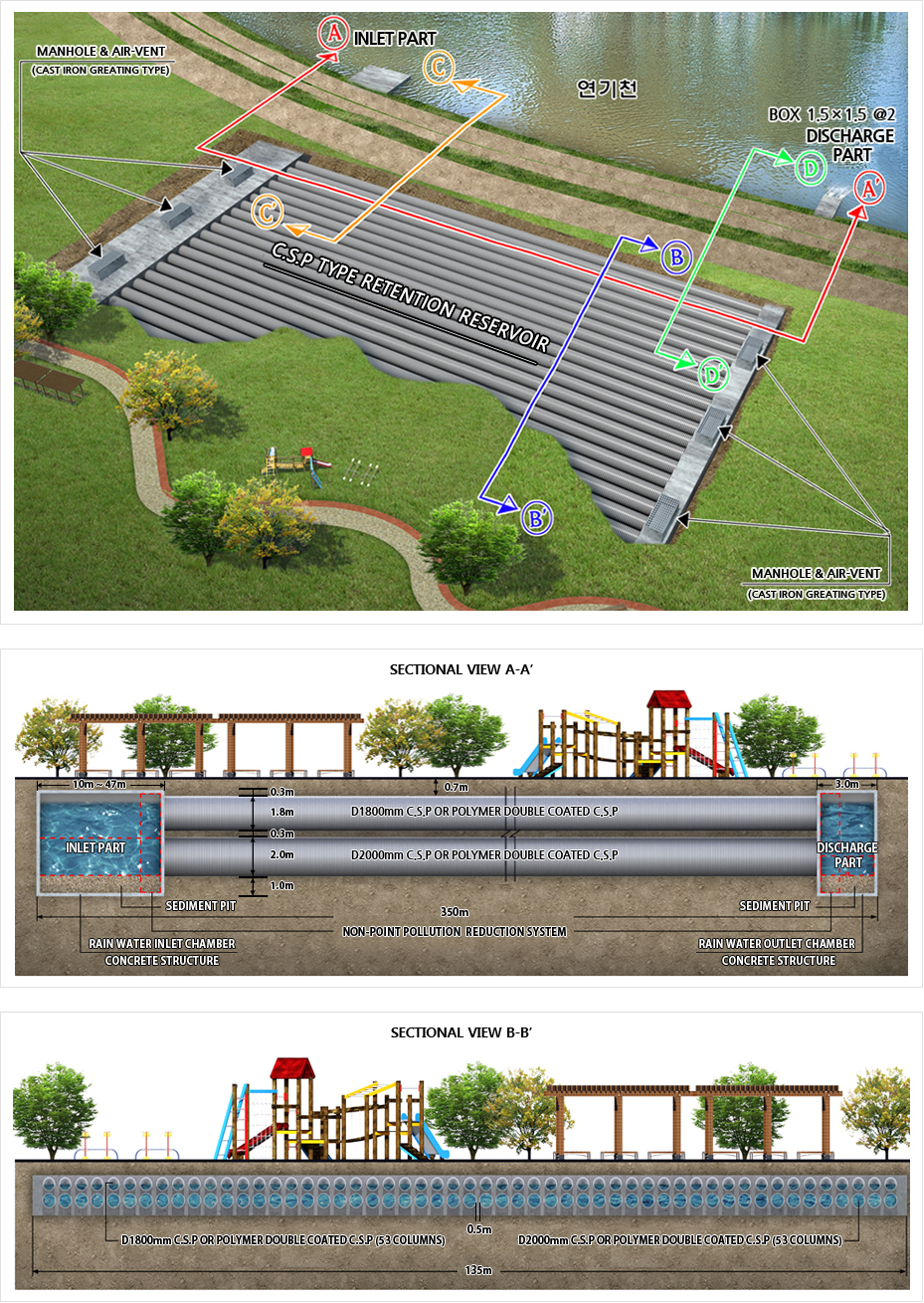

- These specifications apply to C.S.P, POLYMER DOUBLE COATED C.S.P, and WATERTIGHT TYPE POLYMER DOUBLE COATED C.S.P used for various kinds of rainwater drainage pipes, agricultural water pipes, rain & sewage water mixed interception pipes, rainwater detention reservoirs, sewage buffer detention reservoirs, and dirty/waste water detention reservoirs which are used for good water discharge. The range of application may be subject to change due to the on-site environment or requests from the client.

1.2 Applicable standards

- 1.2.1 For types and symbols, the standards specified in KS D 3506 (hot dip galvanized steel plate), KSD 3590, and ASTM A760/760M-00 are used.

- 1.2.2 The design guidelines suggested by the Korean Society of Civil Engineers and AISI shall be applied in structure calculation and review to ensure the structural stability of the C.S.P against ground pressure, traffic load, etc.. However, this applies only to the C.S,P and coated C.S.P (hereinafter, C.S.P) produced according to article 1 and 2.

1.3 Items to be submitted

- The following items shall be submitted pursuant to ”Documents and reports requested by the client.”

1.3.1 C.S.P (Corrugated steel spiral pipe)

- 1.3.1.1 The Korean Industrial Standards KS D 3590 (C.S.P and plate) and ASTM A760/760M-00 & AASHTO applied to the specified hot dip galvanized C.S.P pipes and joint coupling bands used for conduits and other structures.

- 1.3.1.2 For the C.S.P and joint coupling bands used with them, KS D 3506 (hot dip galvanized steel plate and steel tape) and ASTM A929 / 929M or equivalent/stricter standards shall apply, and hot dip galvanized steel plate shall comply with clauses 2.1.1 and 2.1.2.

- 1.3.1.3 For C.S.P, types 1S (SCP 1RS) and 3S (SCP 3RS) can be used, and this shall be selected through a structural calculation of pipe base stability for C.S.P (AISI), taking into account the ground pressure, soft ground, rocky area, and other elements of the on-site environment.

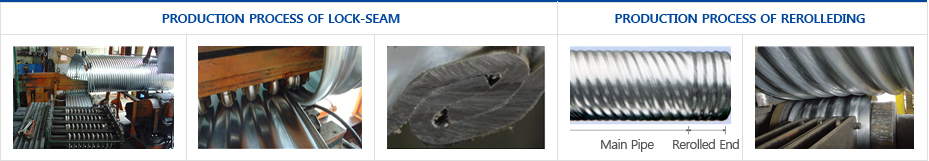

- 1.3.1.4 C.S.P are produced through the spiral LOCK-SEAM joint method. This shall comply with ASTM A760/760M- 00 and related AASHTO regulations and compliance shall be verified.

1.3.2 POLYMER DOUBLE COATED C.S.P

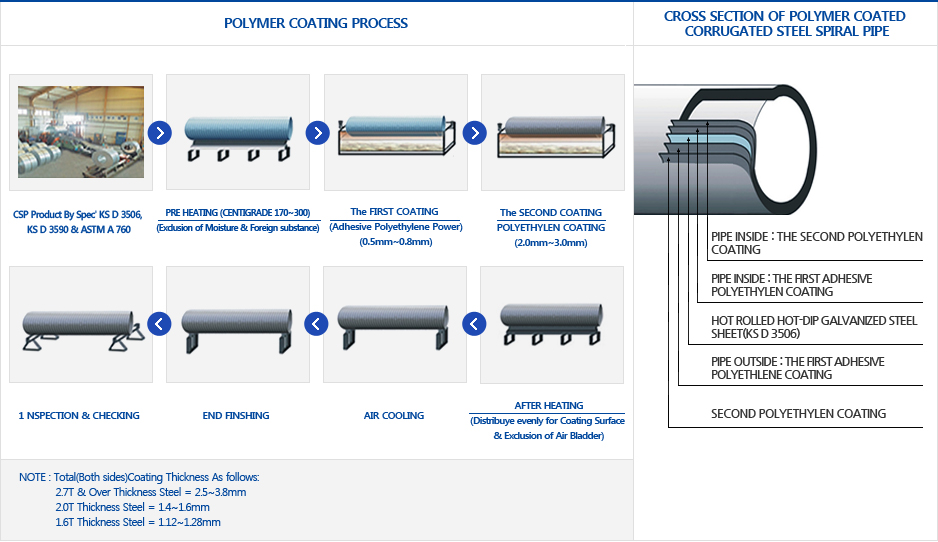

- 1.3.2.1 POLYMER DOUBLE COATED C.S.P are C.S.P produced according to 1.3.1 above, and they shall be coated after production. They shall not be produced after the hot dip galvanized steel plate has been coated because the coating may be damaged during the process of lock-seaming and re-corrugating.

-

- 1.3.2.2 The POLYMER DOUBLE COATED C.S.P is coated twice. The first coating shall be done using polar materials forming POLYMER adhesion to prevent ex-foliation of hot dip galvanized surface and coating layer, and the second coating shall be a high density POLYMER coating with adequate thickness ensuring durability under level 3 & 4 conditions of abrasion.

- 1.3.2.3 Powder coating with heat treatment at a high temperature (170 to 300℃) shall be performed, and the method of attaching PE film shall not be used (non-polar POLYMER is not adhesive to metal).

- 1.3.2.4 For resistance to corrosion and abrasion, the conditions described in clause 1.3.4 shall be met.

- 1.3.2.5 The thickness of the coating shall be equal to that of the steel plate of the C.S.P, or at least 70 to 80 percent thereof. In addition, it is desirable to have a thicker coating on the inside, taking into account incoming abrasive elements such as soil.

- 1.3.2.6 To ensure the adhesiveness of the coating, ex-foliation shall not occur at 25℃, -18℃, or 50℃. Tests of the adhesiveness of the hot dip galvanized steel plate and POLYMER coating shall meet the standards of ASTM A742.

(Note: There are no testing specifications for the adhesiveness of hot dip galvanized steel plates and POLYMER coating in KS.)

1.3.3 WATERTIGHT TYPE POLYMER DOUBLE COATED C.S.P

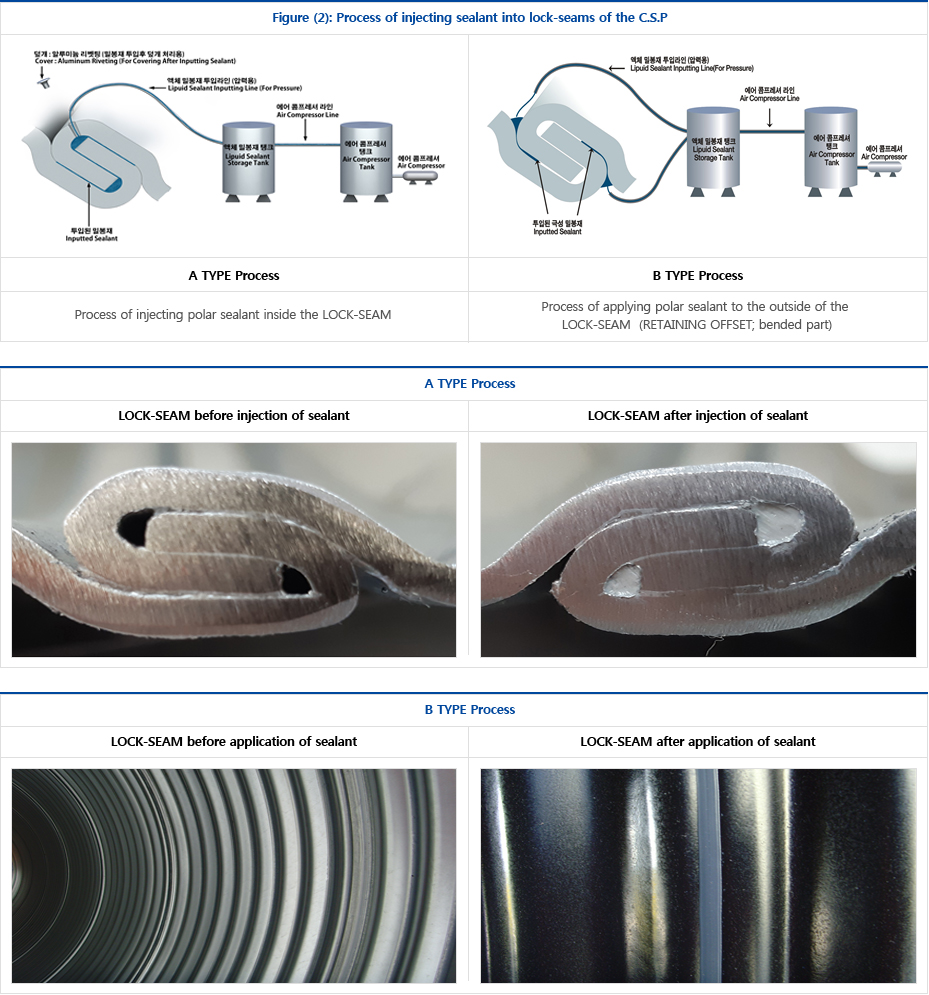

- 1.3.3.1 As shown in Figure (1) below, for all C.S.P, there is a certain amount of leakage at lock-seam parts due to structural characteristics, and ASTM A760/760M & UFGS(2003) standards allow some degree of leakage. Additionally, there might be ground subsidence and sink-hole formation due to water leakage exceeding allowable levels caused by vehicle loads, earthquakes measuring 3.0 or less on the Richter scale, etc.. This could lead to soil and water pollution when the pipes are used for discharging domestic sewage, dirty/waste water, etc.

-

- 1.3.3.2 Watertight Type Polymer Double Coated C.S.P are produced that meet the conditions described in clause 1.3.2 above. In addition, as shown in Figure (2) below, sealant has been injected inside/outside the lock-seam. Therefore, water leakage has been blocked and ground subsidence and sink-hole formation has been prevented so that it can be used as an agricultural water supply pipe, or a drain pipe for domestic sewage and dirty/waste water.

1.3.4 Consideration of corrosive and abrasive elements for POLYMER DOUBLE COATED C.S.P and WATERTIGHT TYPE POLYMER DOUBLE COATED C.S.P

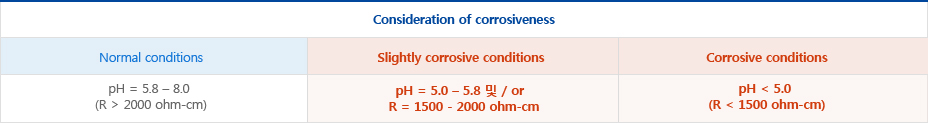

- 1.3.4.1 Consideration of corrosiveness ;

POLYMER DOUBLE COATED C.S.P and WATERTIGHT TYPE POLYMER DOUBLE COATED C.S.P are hot dip galvanized or chrome coated so that they are resistant to corrosion. However, C.S.P shall be POLYMER coated to respond to slightly corrosive and corrosive conditions as much as possible, so that it is possible to enhance durability and corrosion resistance of the pipes under special adverse conditions (pH ≤ 4 or ph ≥ 12) due to salinity, acid rain or other specific causes.

- 1.3.4.1 Consideration of corrosiveness ;

-

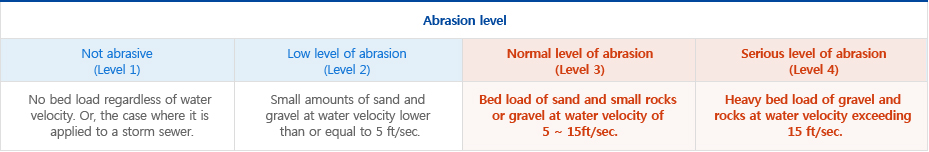

- 1.3.4.2 Consideration of abrasiveness:

In the case of rainwater pipes, they shall be POLYMER coated to protect the hot dip galvanized layer of the C.S.P against incoming fast flow and bed load (sand, gravel, soil and other things) during times of concentrated rain, and ensure durability as far as possible under level 3 & 4 conditions of abrasion.

- 1.3.4.2 Consideration of abrasiveness:

※ In Korea, over 70 percent of the land is mountainous, and when rain falls at a rate equal to or greater than 10 mm/hr, the velocity of rainwater flow can reach 5 to 15 ft/sec, or even greater than 15 ft/sec.

1.3.5 C.S.P TYPE RETENTION RESERVOIR AND DEDICATED FACILITY ;

- The C.S.P pipes used for rainwater detention reservoirs (for temporary detention & discharge or rainwater reuse), sewage buffer detention reservoirs, agricultural water detention reservoirs, and detention reservoirs for dirty/waste water from industrial areas are as described below.

- 1.3.5.1 In cases where soil conditions and aqueous solution are normal [(pH = 5.8 – 8.0 (R > 2000 ohm-cm)] and the velocity of rainwater is slower than or equal to 5 ft/sec (abrasion level 1 & 2), C.S.P meeting the standards specified in clauses 1.3.1, 2.1.1, 2.1.2, and 2.2 can be used for rainwater detention reservoirs (temporary detention & discharge type).

- 1.3.5.2 In cases where soil conditions and aqueous solution are slightly corrosive / corrosive [pH = 5.0 – 5.8 / or R = 1500 – 2000 ohm-cm / pH < 5.0 (R < 1500 ohm-cm)] and the velocity of rainwater is in the 5 ~ 15 ft/sec range or faster (abrasion level 3 & 4), POLYMER DOUBLE COATED C.S.P meeting the conditions specified in clauses 1.3.1, 1.3.2 / 2.1.1, 2.1.2, 2.1.3 / 2.2 can be used for rainwater detention reservoirs (temporary detention & discharge type), agricultural water detention reservoirs, and sewage buffer detention reservoirs.

- 1.3.5.3 In the case that the condition of the soil or aqueous solution is slightly corrosive or corrosive [pH = 5.0 – 5.8 (or R = 1500 – 2000 ohm-cm) / pH < 5.0 (R < 1500 ohm-cm)] and the velocity of rainwater is 5 ~ 15 ft/sec, or, faster than or equal to 15 ft/sec (abrasion level 3 & 4), WATERTIGHT TYPE POLYMER DOUBLE COATED C.S.P meeting the conditions specified in clauses 1.3 and 2 is used for rainwater reuse detention reservoirs, agricultural water detention reservoirs, sewage buffer detention reservoirs, and dirty / waste water detention reservoirs.

- 1.3.5.4 For all rainwater detention reservoirs made of C.S.P, (concrete) structures for non-point pollution facilities (for initial processing of rainwater) shall be properly installed as best suits the site conditions.

- 1.3.5.5 For all detention reservoirs built of C.S.P, proper structures for maintenance, such as for removing soil & sediment, etc., and safety facilities including ventilators for maintenance staff shall be installed..

- 1.3.5.6 For all detention reservoirs made of C.S.P, Air-Vents must be installed at proper locations to ensure smooth inflow and outflow of rainwater. In addition, it is recommended that Air-Vents also be installed on the (concrete) structures for the non-point pollution reduction system (for initial rainwater treatment).

- 1.3.5.7 In cases where ground-water or leachate is found in the location where a C.S.P detention reservoir is to be installed, the ground shall be stabilized through the installation of stone filled drains or perforated drainpipes and water shall be fed back to the detention reservoir using a separate drainage pump.

- 1.3.5.8 The construction standards in clause 3 shall be applied when building C.S.P detention reservoirs.